Tan Delta, also known as the dielectric loss factor or dissipation factor, is one of the main indicators used to assess the condition of the electrical insulation in medium-voltage cables. This measurement is essential for predictive diagnostics in cable networks and directly contributes to failure prevention and improved system reliability.

An insulated cable functions as a capacitive system, since it has two conductors — the main conductor and the metallic shield — separated by an insulating medium. When voltage is applied to the material, the electrodes become polarized, and energy is then stored in the electric field.

In the case of an ideal capacitor, this energy is stored without losses, whereas in real materials, such as the insulation of electrical cables, there is energy dissipation — through heat or other effects. Therefore, the more aged the insulation, the greater the energy loss and the higher the Tan Delta value.

How Tan Delta measurement works

The insulation of a cable acts as a real capacitor, with a dielectric between two conductors. In ideal insulation, the resistance (R) would tend toward infinity, and the resistive current (IR) would be zero. However, in real insulation systems, this resistance is finite, and a resistive current does exist.

Tan Delta is therefore the ratio between the resistive component and the capacitive component of the electric current. The lower this value, the healthier the cable. On the other hand, a high value indicates wear, aging, or potential failures in the system.

Thus, by measuring the Tan Delta in insulated cables, it is possible to diagnose the degree of insulation aging along the entire length of the cable.

Case studies: real-world insights from Tan Delta measurements

To illustrate the practical importance of Tan Delta in insulated cables, we’ve compiled three case studies that show different scenarios encountered in the field — from cables with still-healthy insulation to critical situations with imminent failure risks.

In all cases, the measurement provided valuable diagnostics that guided maintenance and replacement decisions. These examples help demonstrate how to interpret Tan Delta results and what actions can be taken depending on the level of aging detected.

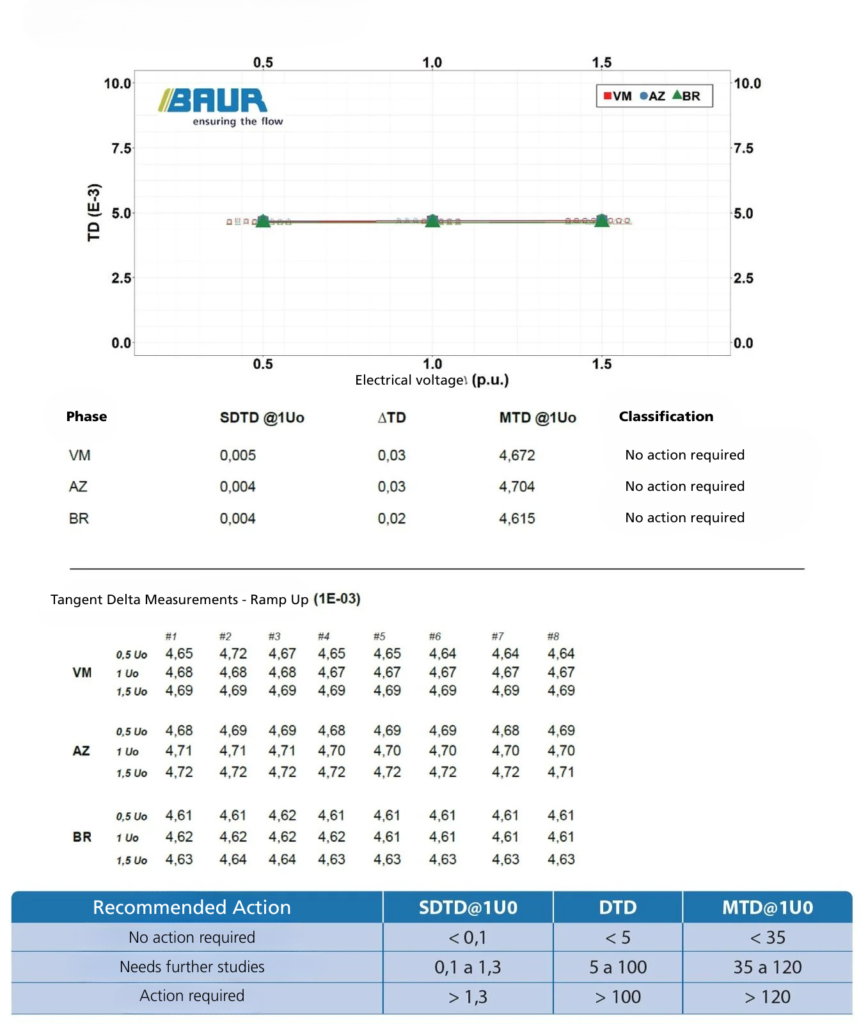

Case study 1: healthy cables in an industrial environment

In this study, single-core 3.6/6 kV Class cables with EPR (Ethylene Propylene Rubber) insulation, installed in conduits in an industrial environment, were evaluated. The cables had been in service for less than 10 years.

According to the IEEE 400.2 – 2024 criteria, the Tan Delta measurement results fell within the “No Action Required” range. This indicates minimal insulation aging and, consequently, a low risk of electrical failure.

It’s important to note that the Tan Delta technique provides an integral measurement — that is, it assesses the insulation condition along the entire length of the cable. If a localized defect exists at a specific point, it may not be detected by this method. Even so, all the cables in the circuit showed consistent results, confirming uniform installation conditions and aging profiles.

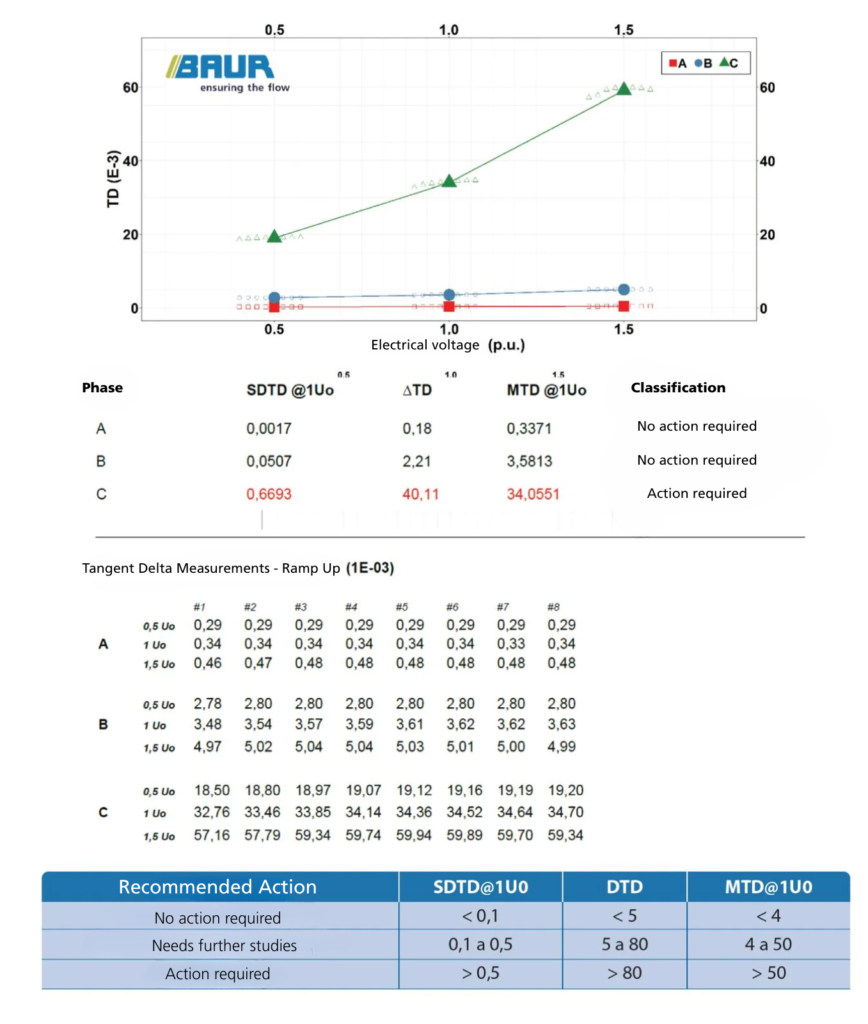

Case study 2: cable showing signs of wear and risk of failure

In this example, three single-core, 20/35 kV rated cables with XLPE (Cross-Linked Polyethylene) insulation were evaluated. The cables had been in service for between 10 and 20 years at a wind farm in the Northeast region of Brazil.

While phases A and B presented results within the “No Action Required” range, the cable from phase C showed significantly different Tan Delta values, corresponding to the classification “Further Study Recommended.”

It is important to note that the Tan Delta value increased with both applied voltage and time — a behavior that may be related to accessory failures or leakage currents. As a result, the recommended actions include:

- Partial Discharge testing;

- Time Domain Reflectometry (TDR);

- Thermographic analysis;

- Replacement of accessories;

- VLF Applied Voltage Testing.

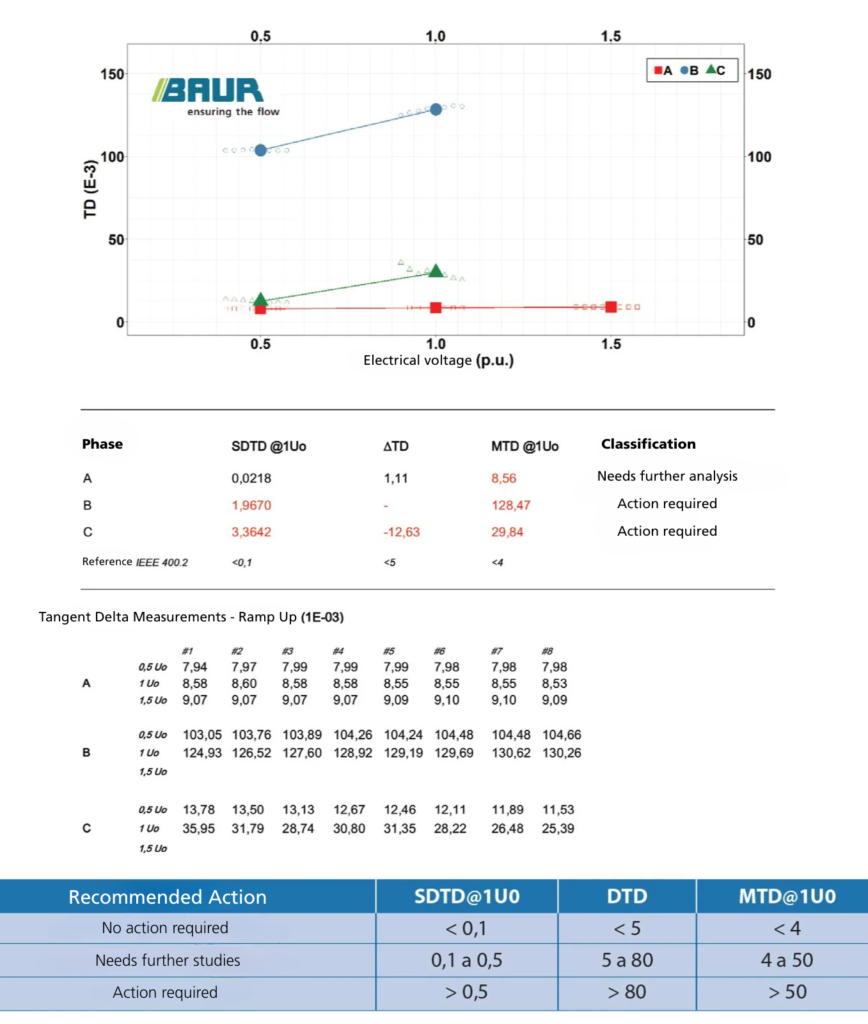

Case study 3: Cable in critical condition with imminent risk of failure

Also located in a wind farm in northeastern Brazil, this study evaluated single-core, 20/35 kV rated cables with XLPE insulation, which had been in service for 10 to 20 years.

Cables from phases B and C showed a rising trend in Tan Delta values, with particular concern for the phase C cable, which experienced dielectric breakdown between 1 U₀ and 1.5 U₀.

This failure was associated with tracking in accessories and leakage currents. Subsequent partial discharge testing confirmed activity in splices approximately 200 meters from the termination point. Replacing the splice resulted in a significant improvement in performance parameters.

Although tests were not performed on the phase B cable due to unavailability, corrective actions were later implemented.

This is a clear example of how Tan Delta testing in insulated cables can help prevent catastrophic failures, justify investment in diagnostic equipment, and enhance asset management in power distribution systems.

Conclusion: the strategic value of Tan Delta measurements in insulated cables

Tan Delta testing in medium-voltage insulated cables is a strategic tool for predictive maintenance. It enables utilities and asset managers to:

- Assess material aging;

- Anticipate potential failures;

- Prioritize interventions based on real data;

- Extend the service life of critical assets.

As the case studies demonstrate, Tan Delta analysis provides valuable insights into the condition of cable insulation, allowing for targeted actions before issues become critical.

Related services

VIOLA TD

BAUR viola TD is an device recommended for performing VLF (Very Low Frequency) withstand test and dissipation factor (Tan Delta) test on insulated cables rated up to 20/35 kV.

FRIDA TD

BAUR frida TD is the recommended device for performing VLF (Very Low Frequency) withstand test and dissipation factor (Tan Delta) test on insulated cables rated up to 12/20 kV.