While Tan Delta measurement allows the evaluation of insulation aging over time, the Partial Discharge (PD) testing technique offers a targeted and precise diagnostic approach focused on detecting localized defects that can evolve into failures in the short or medium term.

This technique is essential for identifying early defects in medium-voltage cables and accessories before they compromise system operation. By locating areas of high electrical stress, it becomes possible to take preventive action, increasing the reliability of the electrical installation.

What are partial discharges?

Partial Discharges are localized dielectric breakdowns that occur in small regions of the insulation of cables or accessories. They generate abrupt charge pulses but do not completely break down the insulation, which prevents protection systems from tripping.

These discharges are caused by the accumulation of localized electrical stress, often related to:

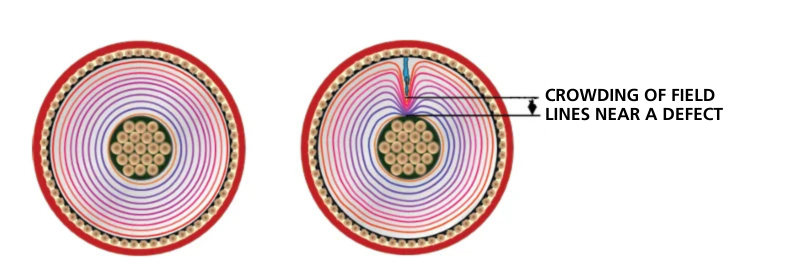

- Water trees;

- Insulation imperfections;

- Distortions in the electric field.

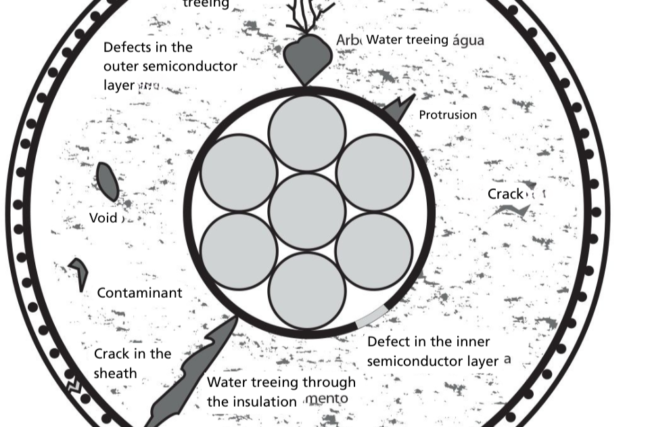

The figures below illustrate how the distortion of electric field lines favors the emergence of discharges which, over time, reduce dielectric strength until causing cable failure.

Partial-discharge-causing defects

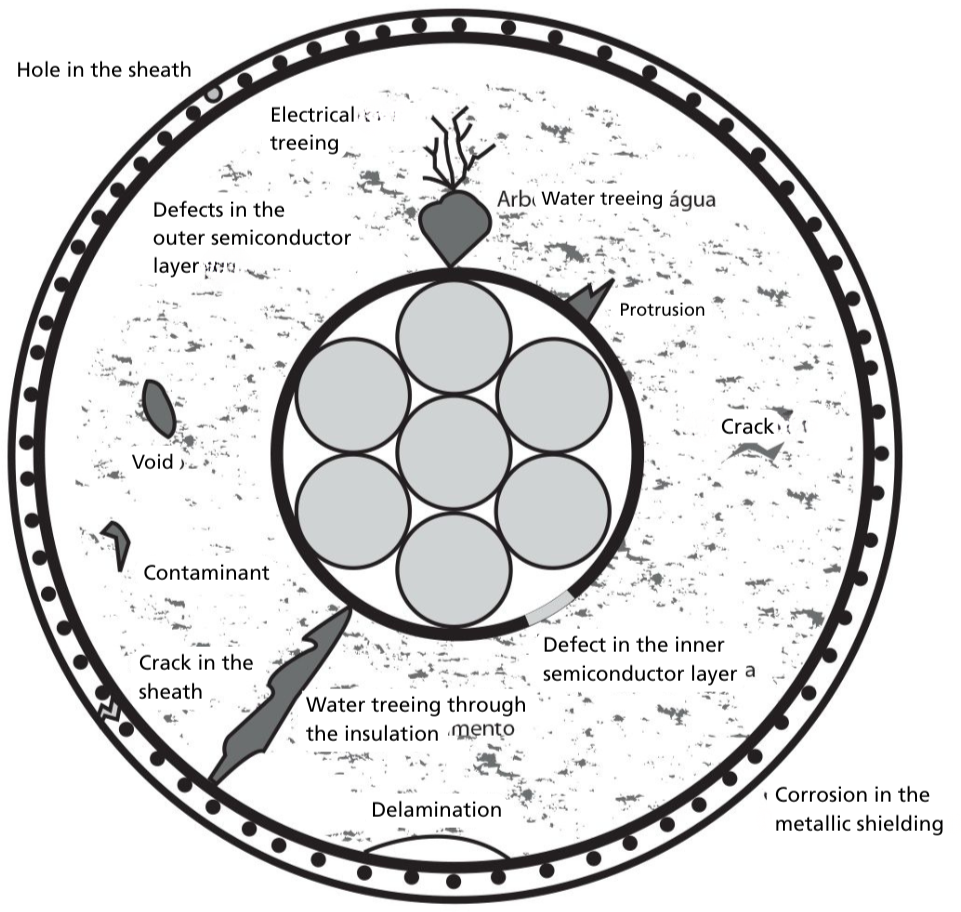

Internal insulation defects in cables can lead to Partial Discharges and evolve rapidly, with failures occurring within minutes or days. Therefore, conventional diagnostics may not be sufficient, since the detection window is narrow.

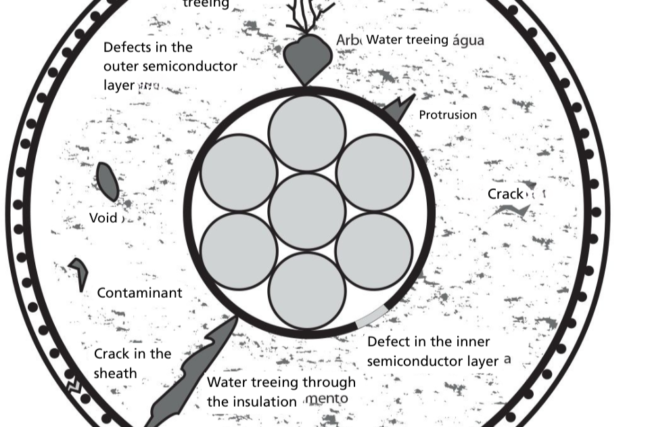

Typical defects include:

- Metallic inclusions or internal voids;

- Mechanical damage;

- Water treeing.

These defects are often identified during VLF applied-voltage tests, both in commissioning and in routine maintenance. The figure below presents visual examples of these defects.

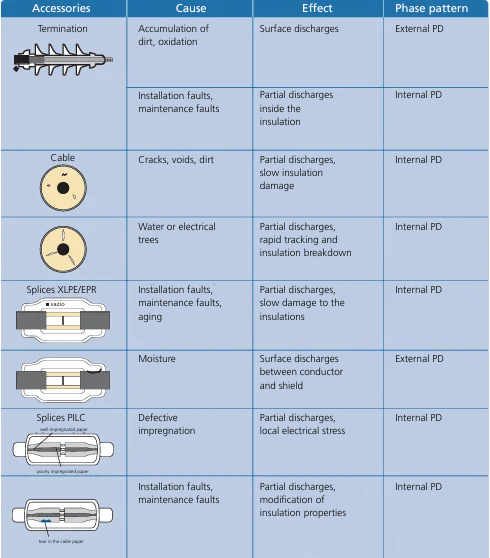

Defects in cable accessories

Field-assembled accessories (terminations and splices) are more susceptible to installation errors such as:

- Incorrect opening of end caps;

- Insufficient cleaning;

- Improper sizing.

Criticality increases in high-voltage systems, requiring greater rigor in procedures. The figure below illustrates common defects that can generate Partial Discharge (PD) activity in accessories.

Technologies for Partial Discharge Testing

There are several technologies on the market for detecting Partial Discharges, but there is little standardization among manufacturers, which can cause confusion when choosing equipment. Among the most widely used are electrical quadrupoles and high-frequency current transformers (HFCT).

The tests are divided into two main categories:

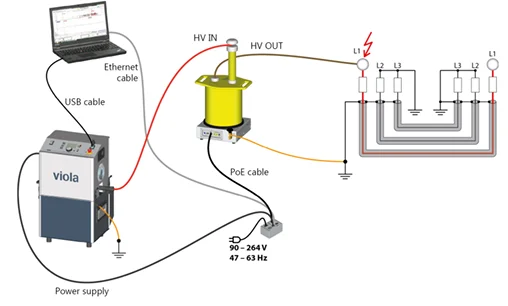

Offline Partial Discharge Tests

Performed with the system de-energized, they require disconnecting the terminations and using an external source to apply voltage.

Main characteristics:

- Control of measurement variables;

- Higher sensitivity and lower noise;

- Defect location via reflectometry;

- Identification of inception and extinction voltages of the discharges.

The equipment records the signals generated during the test and submits them to analysis aided by Artificial Intelligence, allowing events to be classified and quantified. The figure below shows a typical arrangement for this type of test.

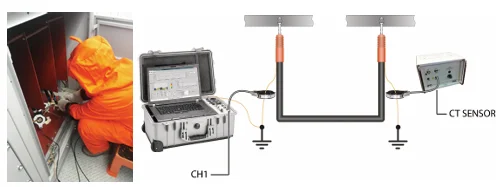

Online Partial Discharge Tests

These are performed with the system energized, using high-frequency current transducers connected to the cable shield, as shown in the figure below:

Optionally, the online test can also be performed via the VDS ports on the switchgear cubicles, if available.

Advantages:

- Continuous monitoring without interrupting operation;

- Applicable to systems with low shutdown availability, such as solar and wind plants.

Disadvantages:

- Higher levels of noise and electromagnetic interference;

- Lower sensitivity;

- Inability to correlate behavior with the applied voltage.

These systems use Artificial Intelligence to filter and identify discharge signals within large volumes of data collected in real time.

Conclusion

The Partial Discharge measurement technique is an essential tool in the predictive maintenance of electrical systems with insulated cables. Its application enables early detection of critical defects, especially in field-installed accessories, where failures are more frequent.

With the appropriate choice between online or offline testing, it is possible to balance measurement sensitivity with the system’s operational availability. Proper identification and treatment of Partial Discharge defects prevents unexpected failures and increases the reliability of the power network, contributing to the safety and continuity of industrial and energy processes.