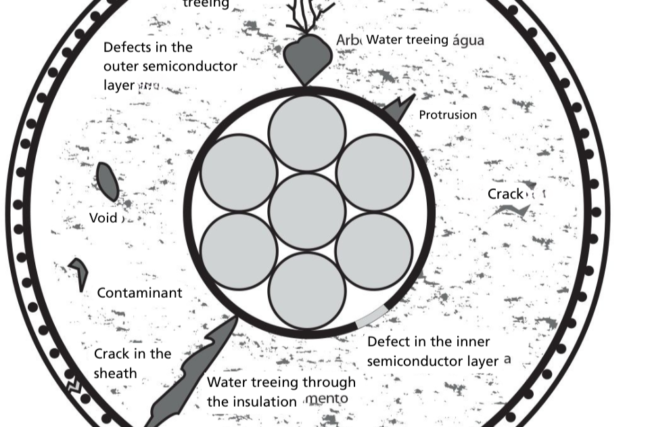

After the detection of Partial Discharge (PD) in insulated cables, the most important—and also the hardest to answer—question arises: does this defect represent a real risk of imminent failure, or can it be monitored?

In practice, most mistakes in predictive maintenance programs are not in the measurement itself, but in the interpretation of the results and in the incorrect assessment of the criticality of the identified defect. As a reference for concepts and procedures for partial discharge measurement, it is common to adopt IEC 60270 (High-voltage test techniques — Partial discharge measurements).

Why Isn’t Partial Discharge Magnitude a Good Standalone Indicator?

It’s still common to see evaluations based exclusively on discharge magnitude, expressed in picocoulombs (pC). However, using this criterion by itself can lead to wrong decisions.

Some typical examples:

- Surface discharges in terminations can reach thousands of pC, yet progress slowly.

- Internal cavities or interface defects in joints can produce low-magnitude discharges (tens of pC), but with a high potential for accelerated degradation.

In other words, magnitude does not automatically equal severity.

Partial Discharge in Insulated Cables and the Role of PDIV and PDEV

PRPD (Phase Resolved Partial Discharge) patterns provide valuable information about discharge repetitiveness, the electrical phase at which it occurs, and how stable the phenomenon is over time.

Although there is still no universal, standardized correlation between PRPD patterns and defect types, comparative analysis—combined with the analyst’s experience—allows for much more robust technical inferences than simply reading pC values.

The trend is that, as databases and artificial intelligence algorithms advance, this interpretation will become increasingly automated and reliable.

When to Replace and When to Monitor?

Practically speaking, some widely adopted technical guidelines are:

- Active PD at U₀ or below. Recommendation: immediate preventive maintenance, especially on accessories.

- PD only under overvoltage and with no progression. Recommendation: controlled monitoring, with periodic re-evaluations.

- Environments with limited outage availability. Strategy: sequential online monitoring, tracking the trend of PD evolution.

Conclusion

Assessing criticality in partial discharge testing requires an integrated view, combining electrical parameters, behavioral patterns, and knowledge of the system. Decisions based on simplified criteria tend to cause both unnecessary interventions and avoidable failures.

More than detecting PD, the real challenge is turning data into consistent technical decisions.

Related services

PD-TAD 62

The PD-TaD 62 is a portable Partial Discharge diagnostic system used in conjunction with a VLF source for diagnosing medium-voltage insulated cables.

FRIDA TD

BAUR frida TD is the recommended device for performing VLF (Very Low Frequency) withstand test and dissipation factor (Tan Delta) test on insulated cables rated up to 12/20 kV.

VIOLA TD

BAUR viola TD is an device recommended for performing VLF (Very Low Frequency) withstand test and dissipation factor (Tan Delta) test on insulated cables rated up to 20/35 kV.

LIONA

liona is a portable online PD spot tester for measuring and locating Partial Discharges in cables and switchgear during normal mains operation.