Effectively managing medium-voltage cable networks is crucial for optimizing performance and costs associated with the life cycle of these assets, as well as ensuring the safety and availability of operations. Whether during commissioning, regular maintenance, or the acceptance and post-repair phase, it is important to adopt maintenance strategies for medium-voltage networks that can mitigate and prevent failures and diagnose the technical condition of individual circuit elements (cable segments, joints, terminals).

The ideal maintenance strategy for a medium-voltage network should consider different contexts, such as the current system conditions, the history from civil work, available maintenance techniques, as well as the team’s knowledge of the dynamics and life cycle of insulated cables and system components, which may have different characteristics and usage times.

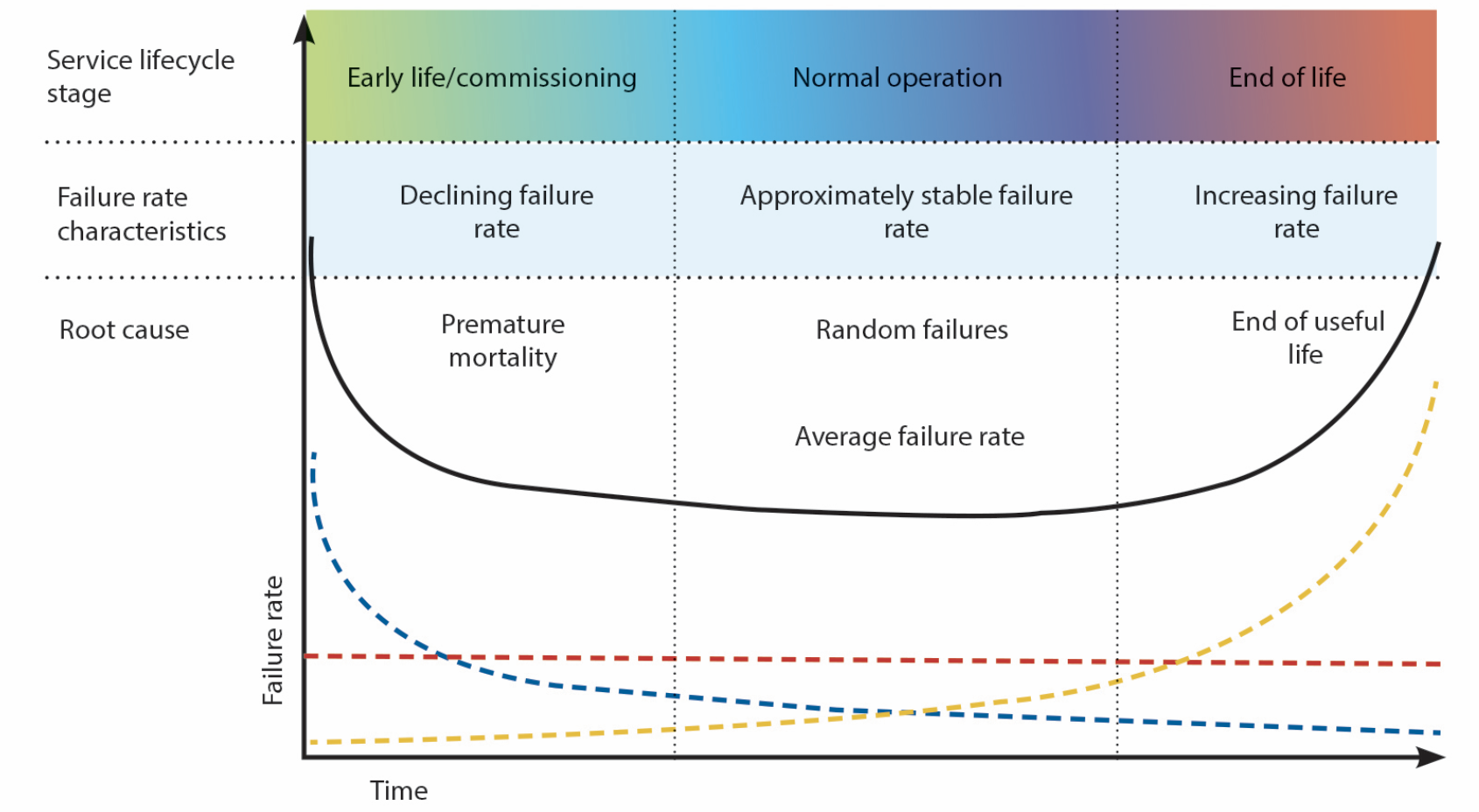

Bath Tub Curve and Failure Probability in Cables

Like other industrial products, the components of a medium-voltage network, such as cables, joints, and terminals, exhibit a failure probability curve over time, known as the “bath tub curve.” This curve can be obtained by superimposing three curves: the one indicating the probability of premature failures, the one indicating the probability of failures due to defect formation during the half-life, and the curve that defines the probability of failure due to natural wear and aging.

Failure Probability Curve as a Function of Application Time for Medium-Voltage Insulated Cables

Common Maintenance Challenges

The maintenance management strategy must be capable of mitigating and preventing failures, including:

- Circuit shutdown: Failures in any part of the cables can result in a total shutdown of the circuit, making operation impossible.

- Long fault location time: The urgent need to locate faults can take hours or even days, resulting in a loss of energy production.

- Economic loss: Total or partial circuit shutdowns, whether for fault location or scheduled maintenance, have impacts on operation.

Maintenance Strategies

Maintenance techniques can be classified as corrective, preventive, and predictive.

1. Corrective Maintenance

Corrective maintenance is the set of actions performed after a failure occurs. Although necessary, this approach is often costly and directly impacts the production and sale of energy. If the failure occurs in sections far from the substations, more distant generating units can be disconnected, minimizing capacity loss. However, failures in the initial sections require a total shutdown of generating units, resulting in high costs.

2. Preventive Maintenance

Preventive maintenance involves procedures to reduce the likelihood of failures. This includes reconditioning and replacing defective components. Performing insulation tests on cables is a common practice, but it should be done with caution to avoid reducing the assets’ service life.

3. Predictive Maintenance

Predictive maintenance is based on continuous monitoring of asset conditions. Tracking indicators and analyzing data allows resources to be directed to assets that truly need maintenance. This approach avoids corrective maintenance and unnecessary replacements, increasing the reliability and availability of assets.

Next, we will detail the three main types of maintenance recommended for medium-voltage networks.

Corrective Maintenance in Medium-Voltage Networks

Corrective maintenance in medium-voltage networks involves a set of actions and procedures aimed at repairing, replacing, or restoring the characteristics of a system after a failure. Despite all the available technology and existing diagnostic techniques, some failure events may still compromise the network. Therefore, it is essential to develop a contingency plan for the quick location and execution of repairs.

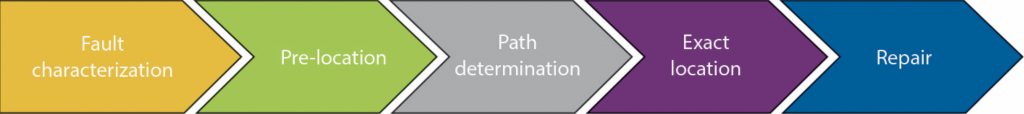

Locating a fault in a directly buried insulated cable is not a trivial process, but it follows a traditionally established methodology, outlined in the figure below:

Failure Characterization: The first step involves conducting tests to confirm and characterize the failure. The information obtained in this step will guide the procedures used in all subsequent stages.

Pre-location: In this step, the fault location will be estimated approximately. It is perhaps the most critical stage of the entire process, as it often involves a higher need for technology and trained teams.

Path Determination: After the pre-location stage, the distance from the measurement point to the fault position will be relatively well estimated. However, it is necessary to know the path of the cables. Therefore, the path determination stage is extremely important to locate the fault point with more accuracy and speed.

Exact Location and Repair: In the exact location stage, the fault position is determined with precision, usually within a few centimeters, allowing for the excavation of a trench and, if necessary, the subsequent repair.

The IEEE Guide for Fault-Locating Techniques on Shielded Power Cables (IEEE 1234, 2007) and the CIGRE Technical Brochure Fault Location on Land and Submarine Links (CIGRE WG B1.52 773) are excellent resources for more detailed information on fault location techniques in insulated cables.

Preventive Maintenance in Medium-Voltage Networks

Preventive maintenance in medium-voltage networks involves the execution of procedures to reduce the likelihood of failures or promote the reconditioning of assets. In other words, these are procedures performed to prevent failures. We can segment them into two categories: those that involve the application of medium voltage and those that do not.

Preventive Maintenance Procedures in Medium-Voltage Networks

Procedures that do not use medium voltage are generally related to cleaning and maintaining accessories, reconditioning surfaces, tightening connectors, among others. These procedures reduce the degradation rate of assets and are therefore considered preventive. However, it is important to highlight that, for medium-voltage cables, their functionality is limited. This is because critical defects usually develop in the internal structures of the cables or in areas not accessible for inspection.

Procedures that use medium voltage are those that typically provide the best results in reducing the number of failures and occurrences during operation. These procedures are used to verify the minimum performance condition of assets, preventing them from being put into operation under critical conditions. For cables, various types of tests can be applied. The most important and commonly used are tests applied to the insulation, using very low frequencies, and to the sheath.

Predictive Maintenance in Medium-Voltage Networks

Predictive maintenance in medium-voltage networks has become increasingly relevant in all areas of maintenance. From a management perspective, it is very useful to know the state of the cables for cost predictability. This information also contributes to operational planning and directing resources for preventive maintenance. Furthermore, predictive action allows for contingency planning (in the event of failures) and cable replacement when necessary. To gather this information, we recommend predictive maintenance techniques.

Predictive Maintenance Techniques in Medium-Voltage Networks

The table below presents the most commonly used techniques worldwide for predictive monitoring of medium-voltage insulated cables. Generally, there are two types of techniques: those that provide global information about the condition of the cables and those that perform localized assessments.

| Technique | Assessment | Main objectives | Method |

| Tan Delta | Integral | Insulation degradation and identification of irregularities | Offline |

| Frequency Domain Spectroscopy | Integral | Insulation degradation and identification of irregularities | Offline |

| Time Domain Spectroscopy | Integral | Insulation degradation and identification of irregularities | Offline |

| Partial Discharge Measurement | Localized | Identification of defects in insulation and accessories | Online or offline |

| Time Domain Reflectometry | Localized | Evaluation of metallic shielding and identification of various irregularities | Offline |

| Frequency Domain Reflectometry | Localized | Evaluation of metallic shielding and identification of various irregularities | Offline |

| Thermographic Analysis | Localized | Identification of defects that cause heating points in cables | Online |

| DC Polarization and Depolarization | Integral | Insulation evaluation | Offline |

| Insulation resistance (DC) | Integral | Insulation evaluation | Offline |

| Shielding Resistance Measurement | Integral | Evaluation of metallic shielding | Online and offline |

| Conductor Resistance Measurement | Integral | Identification of irregularities associated with high-resistance points | Offline |

Global and Localized Maintenance Techniques

Global maintenance techniques in medium-voltage networks help identify certain irregularities and indicate the aging and degradation state of insulation. However, they may not be sensitive to specific types of localized defects. On the other hand, localized techniques pinpoint the exact position of irregularities but are applicable only to certain types of defects.

Currently, Tan Delta and Partial Discharge measurements have gained increasing importance in the market, as they work complementarily, enhancing the efficiency of diagnostics.

Related services

PROTRAC ®

With protrac®, it is possible to precisely locate acoustic, electromagnetic, and sheath faults in insulated cables, as well as trace circuit routes.

VIOLA TD

BAUR viola TD is an device recommended for performing VLF (Very Low Frequency) withstand test and dissipation factor (Tan Delta) test on insulated cables rated up to 20/35 kV.

SYSCOMPACT 400 PORTABLE

The Syscompact 400 Portable from BAUR is a comprehensive system for fault location in medium-voltage insulated cables, including cables with a nominal voltage of 20/35 kV.